Precision Filling for Fine Chemicals:

"Corrosion-Resistant & Precise"

Engineered for strong acids, alkalis, high volatility, and special viscosity liquids. Hozun provides SS316L & PTFE material options with anti-drip design to ensure production safety.

View Recommended ModelsChallenges in Chemical Filling

Are you facing risks with corrosive, volatile, or high-value materials?

Corrosion & Leakage

Strong acids/alkalis cause rapid aging and leakage of seals and pipes, increasing maintenance costs and safety risks.

Dripping & Evaporation

Volatile liquids escape easily, or nozzles drip after filling, leading to waste of expensive raw materials and pollution.

Inconsistent Accuracy

Traditional equipment struggles to maintain consistent filling volumes with liquids of varying viscosity or particulates.

Compatibility & Precision Control

Hozun selects the optimal wetted materials and pump types based on liquid characteristics to solve chemical processing challenges.

| Challenge | Hozun Solution |

|---|---|

| Acid/Alkali Corrosion | SS316L Stainless Steel / PTFE (Teflon) |

| Dripping Issues | Servo-controlled "Suck-back" Nozzles |

| High Volatility | Diving Nozzle (Subsurface Filling) |

| High Precision | Metering / Peristaltic Pump (< ±1% Error) |

Strict Material Certification & Safety

Ensuring long-term stable operation compliant with chemical industry safety and quality standards.

Material Certificates

SS316L / PTFE CertsDurable Components

Chemical resistant seals (Viton, FFKM)

Precision Testing

FAT with actual liquid to ensure accuracy

Safety Options

Explosion-proof configuration available

Recommended Models

From laboratory small-batch mixing to chemical mass production lines.

Selection Guide

R&D / Small Batch ➝ Choose Semi-Auto / Tabletop

Mass Production ➝ Choose Automatic Line

Semi-Auto High Precision Filler

- Wetted parts available in SS316L or PTFE for various chemicals.

- Flexible operation, ideal for lab R&D and pilot runs.

- Features anti-drip suck-back function for a clean workspace.

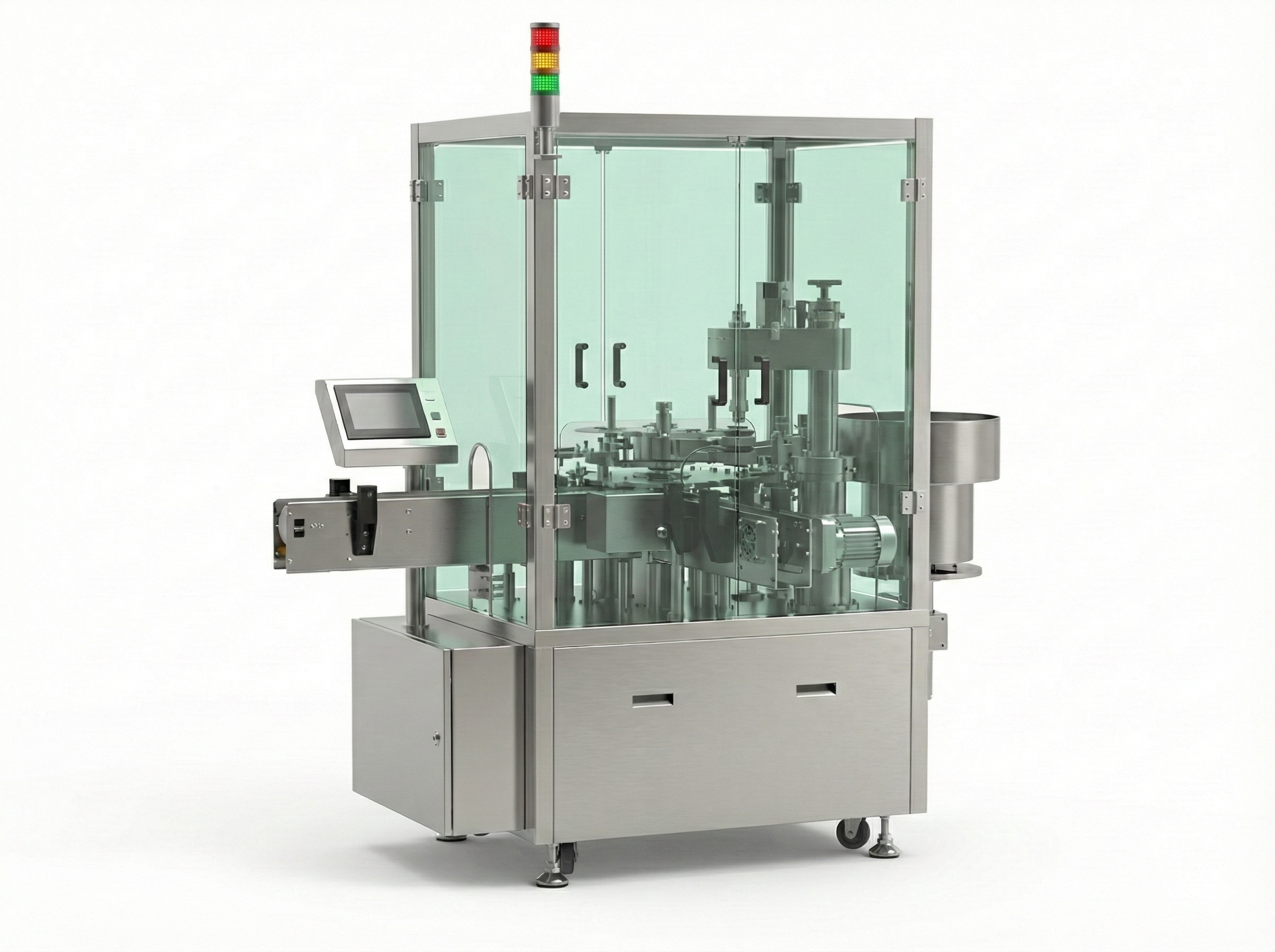

Automatic Chemical Packaging Line

- Modular Design: Integrated Feeding, Diving Filling, and Capping.

- Optimized nozzle design for foaming or volatile liquids.

- Continuous production reduces manual contact with chemicals.

Don't Let Corrosion & Errors Limit Your Capacity

Whether it's corrosive solvents or high-value essential oils, Hozun engineers can plan the most stable solution for you.