Precision Aseptic Filling Solutions

Eliminate cross-contamination risks and streamline your cGMP cleaning validation process with Hozun's advanced peristaltic pump technology.

Challenges in Traditional Filling

Facing bottlenecks with piston pumps in strict regulatory environments?

Cross-Contamination

Traditional mechanisms have dead angles that are hard to clean, increasing the risk of residue on metal contact surfaces.

Tedious Validation

Lengthy Cleaning Validation processes during product changeovers consume valuable production capacity and lab resources.

High Material Loss

Significant residue in traditional piping systems leads to hidden costs, especially for high-value biological agents.

Non-Contact Filling: Born for Purity

Hozun utilizes high-precision servo-controlled peristaltic pump technology to achieve complete isolation between the liquid and mechanical structures.

| Process Requirement | Hozun Solution |

|---|---|

| Contamination Control | Single-use System (Disposable Tubing) |

| Cleaning Validation | No CIP/SIP needed; Simply change the tube. |

| Filling Accuracy | Servo Control ±0.5% (Depending on viscosity) |

Built for Global Compliance Standards

IQ/OQ Support

Validation ProtocolsUSP Class VI

Material CertificatesHygienic Design

Sanitary construction, easy to clean.

High Versatility

Ampoules, Vials, Eye Drops.

Recommended Models

Selection Guide

For R&D / Pilot Run ➝ Choose Tabletop Series.

For Mass Production ➝ Choose Automatic Monoblock.

Tabletop High-Precision Filler

- Compact design, fits in Bio-safety Cabinets or LAF benches.

- Smart recipe memory for quick parameter switching.

- Supports foot pedal or optical sensor triggering.

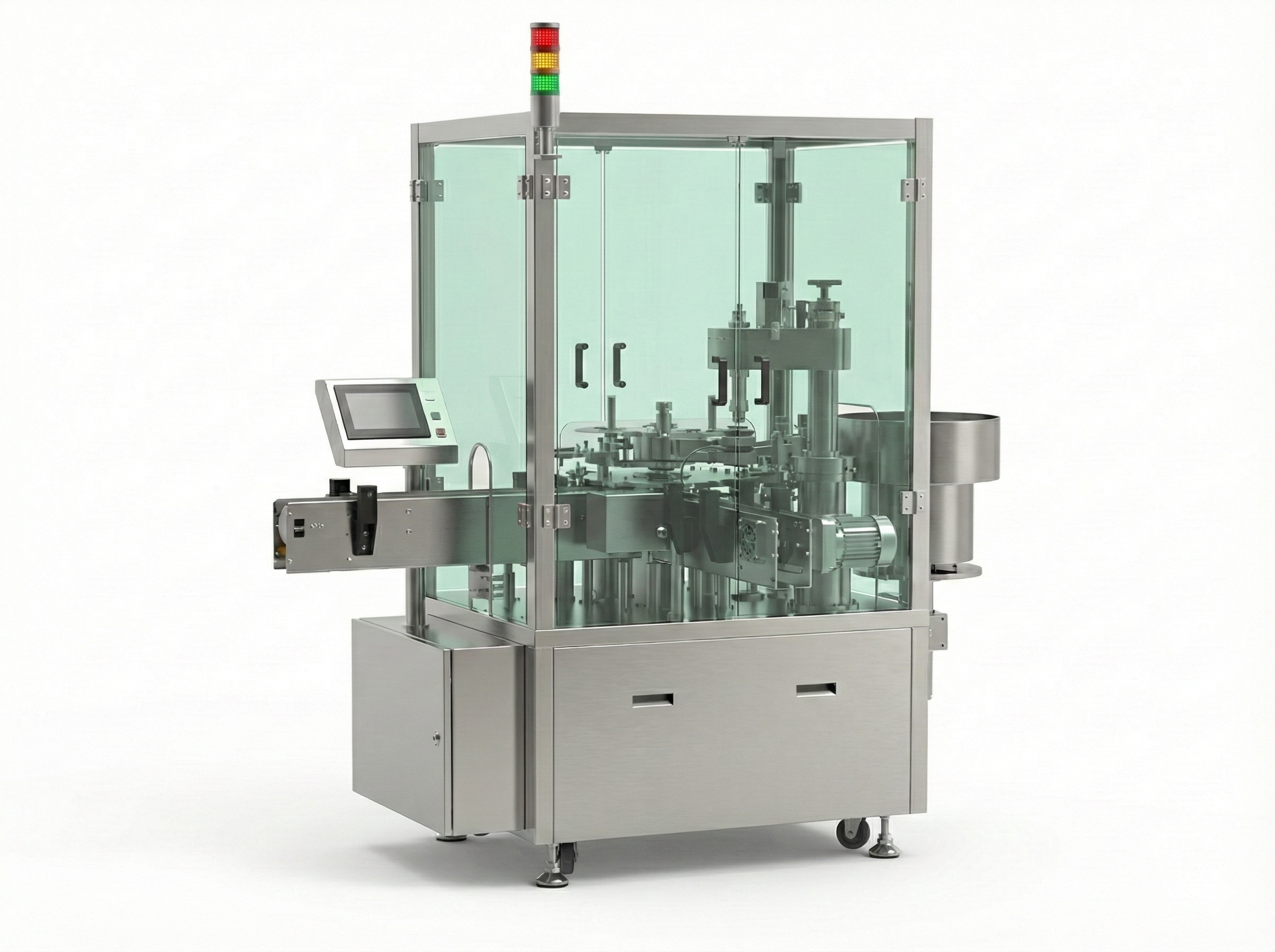

Automatic Monoblock System

- Integrated Washing, Filling, and Capping in one compact unit.

- Optional FFU (Fan Filter Unit) for clean air environment.

- Nitrogen Purging capability for oxygen-sensitive products.

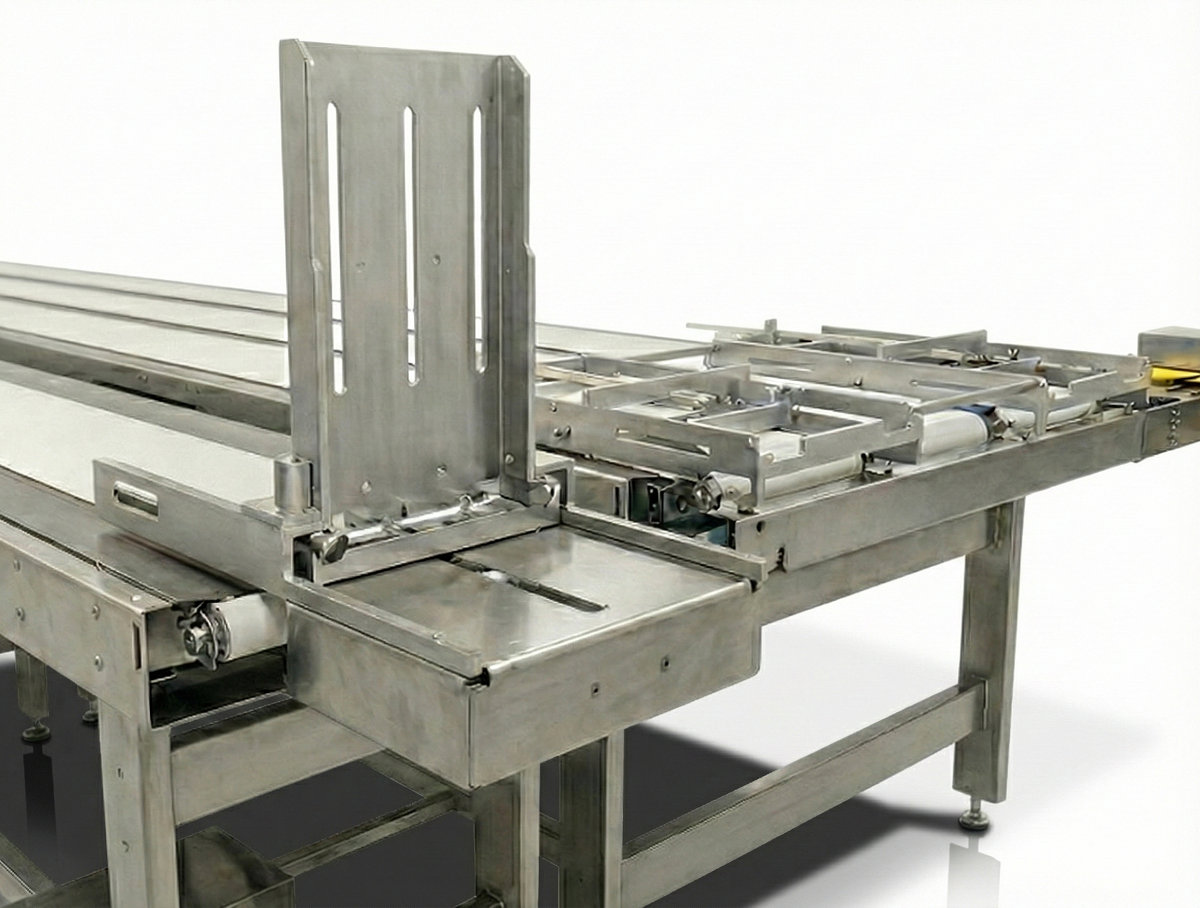

Automatic Petri Dish Filler

- Automated stacking/unstacking reduces manual contamination.

- Built-in UV sterilization ensures an aseptic filling environment.

- Precise quantitative filling for level agar surfaces.

Don't Let Equipment Hinder Your cGMP Compliance

From 1ml precise reagents to high-speed vaccine lines, Hozun engineers are ready to configure the perfect solution.