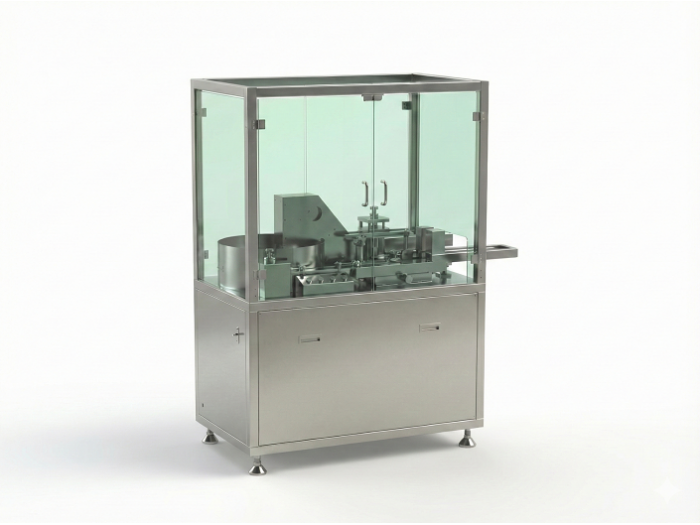

UCB-60 Automatic

Rotary Bottle Unscrambler

The Foundation of an Automated Packaging Line

60 BPM · Round/Square Bottles · Auto Feeding

Eliminate Manual Bottlenecks. Replace manual feeding with high-speed, consistent supply.

The UCB-60 handles diverse bottle shapes at 60 BPM, saving labor and ensuring hygiene.

SUS304 Construction · Variable Speed Control

Speed

MAX 60 BPM

ROI Focused

Why Automate Bottle Feeding?

Manual feeding is slow, unstable, and unhygienic. Automating this step is critical for line efficiency.

Cut Labor Costs

Manual feeding manages only 20-30 BPM. The UCB-60 hits 60 BPM, allowing one person to manage the entire line. ROI in 6 months.

Versatile Compatibility

Handles diverse sizes of round and square bottles by simply changing molds or adjusting rails. Perfect for high-mix production.

GMP Hygienic

All contact parts are SUS304. Optional dust cover available. Eliminates secondary contamination from manual handling.

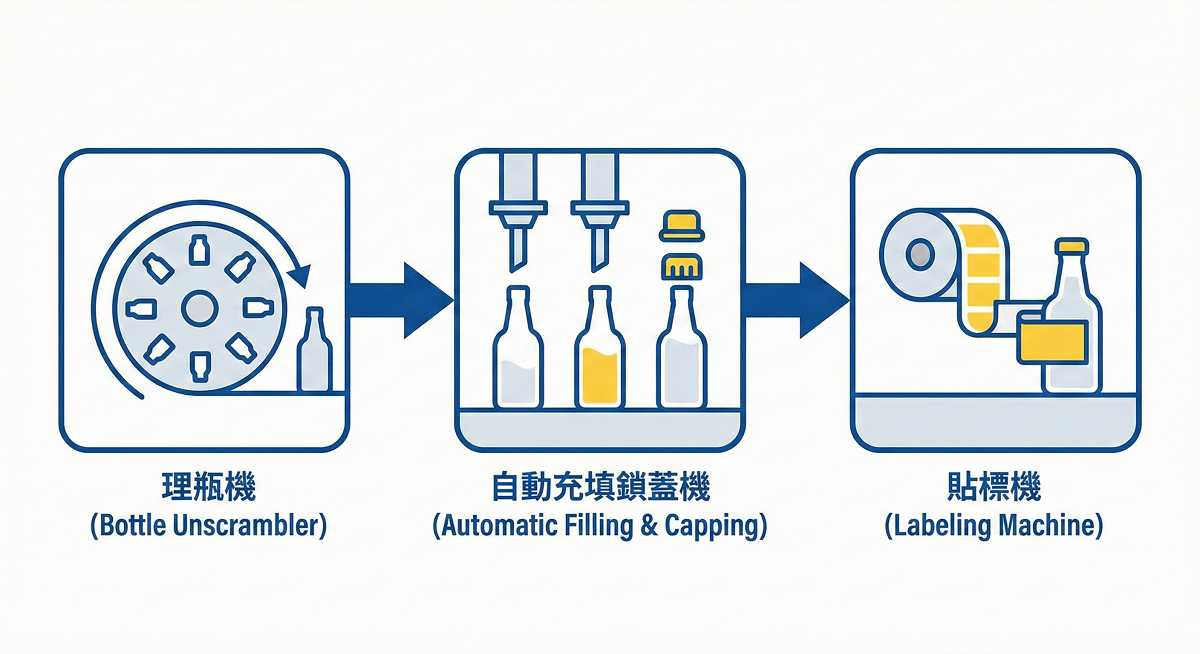

Seamless Line Integration

Designed to feed perfectly into the FH Series Filling Machines.

1. Loading

Dump bottles into hopper

2. UCB-60 Sorts

Orients & stands bottles

We offer full line planning (Unscrambling -> Filling -> Capping -> Labeling)

Consult Line Solution →Specifications

Features variable speed control to perfectly match your filling line speed, preventing jams or starvation.

Power Supply

AC 220V / 50-60Hz

Speed

40 - 60 BPM (Variable)

Bottle Diameter

Φ20mm - Φ100mm

Material

SUS304 Stainless / Anodized Aluminum

Optional Accessories

- Dust Cover: Reduces noise and keeps bottles clean.

- Large Hopper: Increases storage, reduces refill frequency.

- Ion Air Cleaner: Removes dust/static inside bottles.

- Changeover Molds: For special shaped bottles.

Unsure if your bottle fits?

Request Demo VideoSelection Guide

Advice from our automation engineers.

What is a Bottle Unscrambler?

It's the front-end core of an automated line. It takes randomly dumped bulk bottles, orients them, and feeds them upright onto a conveyor. It eliminates repetitive manual labor.

Rotary vs Linear

- Rotary (UCB-60): Compact, simple structure, cheap mold change parts. Ideal for high-mix lines.

- Linear: Very fast but bulky and expensive changeovers. Best for single-product mass production.

FAQ

Can UCB-60 handle square bottles?

Yes. UCB-60 can handle round, square, and flat bottles by changing molds and adjusting rails.

How fast is it?

Max speed is 60 BPM. It has a Variable Frequency Drive (VFD) to adjust speed to match your filler.

What if my bottles scratch easily?

For sensitive materials like PET or mirror-finish bottles, we offer optional Teflon lining and soft guides to prevent scratches.