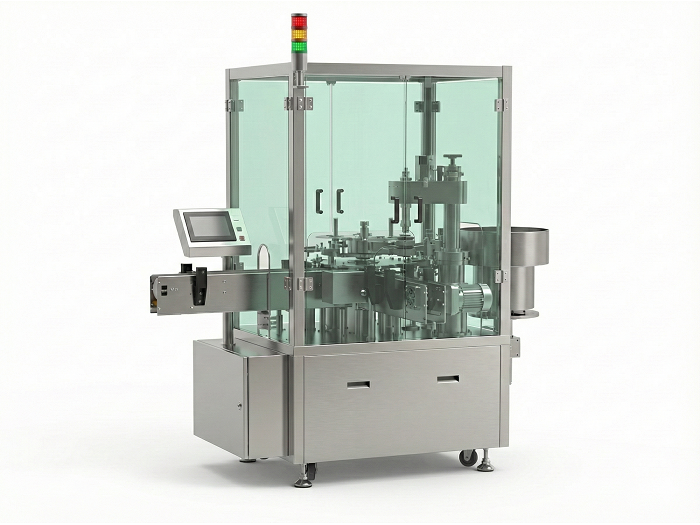

Servo Controlled Filling

& Capping System CSF-100

Engineered for cGMP Pharma & Aseptic Processes. Integrating servo torque control and nitrogen purging for the highest standard of liquid packaging.

.png)

Core Design Philosophy

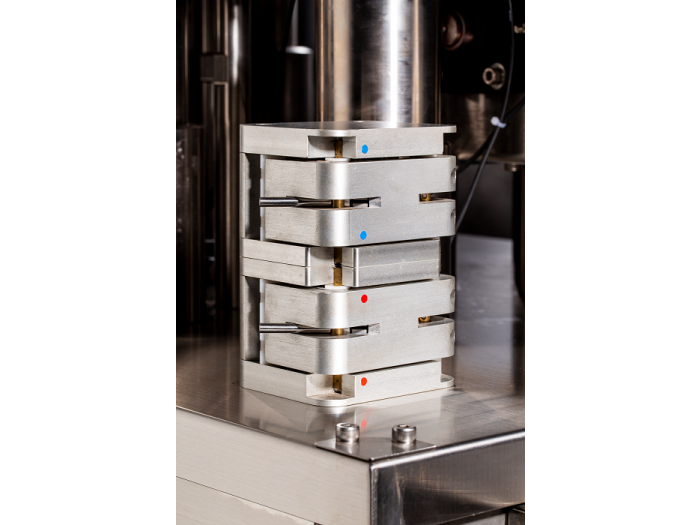

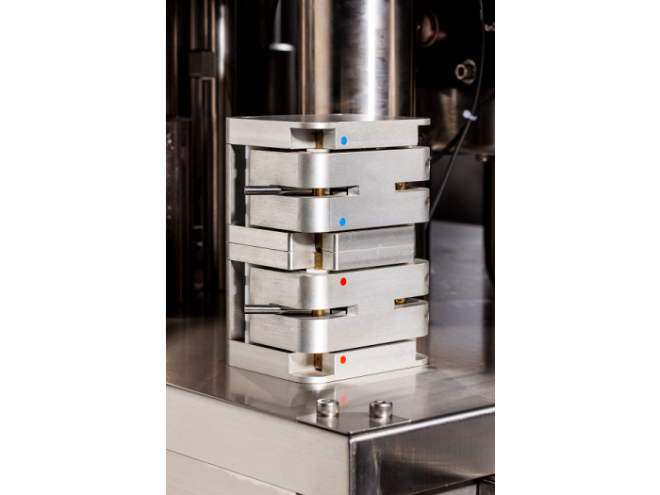

Digital Torque Management

Precise capping torque (N-m) control via Servo Motor feedback, eliminating mechanical friction plates and supporting data logging for Data Integrity.

Aseptic / Easy-Clean

Cantilever structure separates drive zone from production zone. Pre-configured for LAF (Laminar Air Flow) integration to achieve Class 100 cleanliness.

Tool-Free Changeover

Modular parts allow switching between bottle formats in under 15 minutes without tools, maximizing uptime for CMO/CDMO facilities.

Applications & Solutions

Eye drops, Reagents:

Integration of automatic plug insertion, nitrogen purging, and micro-precision filling (±0.5%).

Serums, Ampoules:

Anti-drip nozzles designed for volatile liquids, supporting various irregular bottle capping.

E-liquids, AB Glues:

Specialized piston pumps available for high-viscosity liquids to prevent stringing and clogging.

CSF-100 Specifications

| Bottle Range | 10ml - 100ml (Standard) |

|---|---|

| Capacity | 30 - 50 BPM (Liquid dependent) |

| Capping Tech | Servo Motor Torque Control (±1% Accuracy) |

| Filling Accuracy | ±0.5% - 1.0% (Pump dependent) |

| Material | Contact parts SUS316L / Structure SUS304 |

| HMI Control | Mitsubishi PLC + 7" Touchscreen |

| Validation | Full IQ/OQ Documentation Support |