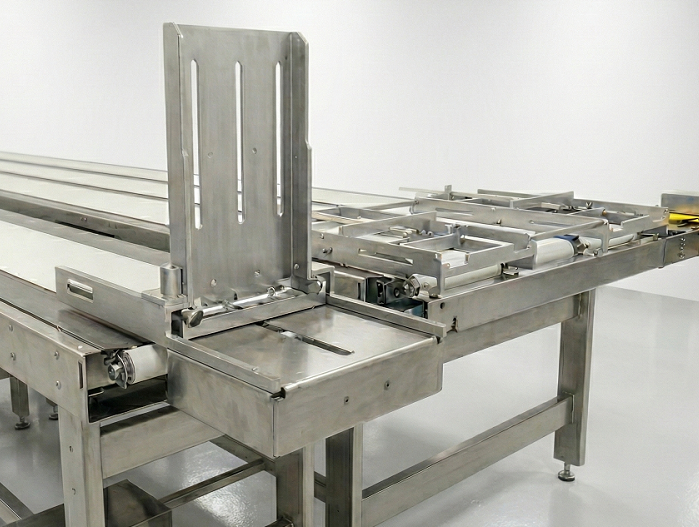

Automatic Petri Dish

Filling System FD-300

Engineered for Large-Scale Microbiology Labs. Delivering 900 dishes/hour with precision bubble-free filling and automated stacking.

Industries & Applications

High-Throughput Prep:

Perfect for mass production of TSA, PDA, and other media plates, ensuring consistent thickness across batches.

Agri-Biotech:

Specialized pump modules handle high-viscosity plant media smoothly, preventing clogging and improving seedling survival.

Sterile Integration:

Floor-standing design integrates seamlessly with cleanroom partitions, meeting strict sterility standards for pharma production.

Core Advantages

Hygienic Design

Cleanroom-grade SUS304 body with optional UV-C sterilization to ensure a contamination-free filling environment.

Precision Pumping

Patented anti-drip suck-back technology ensures a bubble-free, mirror-flat surface for accurate colony counting.

Smart Stacking

Fully automated de-stacking, lid opening, filling, and re-stacking. Handles up to 900 dishes per hour hands-free.

Technical Specifications

| Dish Diameter | Ø90mm (Standard) / Ø55mm, Ø150mm (Optional) |

|---|---|

| Throughput | 600 - 900 dishes / hour |

| Filling Range | 1ml - 100ml (±1% Accuracy) |

| Pump System | Precision Peristaltic Pump (Soft-Start) |

| Sterilization | Optional: UV-C Module |

| Power Supply | 110V / 220V Single Phase, 50/60Hz |