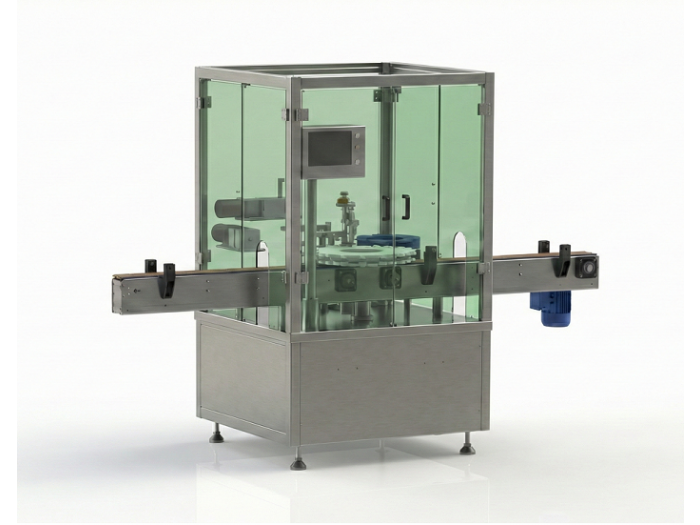

Automatic Filling &

Plugging System FP-120

Designed for Eye Drops, Essential Oils & Diagnostic Reagents. Integrating High-Precision Filling and Automatic Plug Insertion.

Key Advantages

Zero Waste Filling

Engineered for high-value liquids (essential oils, eye drops). Features advanced suck-back technology to ensure "No Drip, No Splash", maximizing yield.

GMP Compliant

Eliminates contamination risks from manual insertion. Precision mechanical grippers insert plugs vertically and gently, meeting strict hygiene standards.

Compact Monoblock

Utilizes a starwheel system to integrate filling and plugging. Saves 40% floor space compared to linear lines, ideal for cleanrooms.

Applications & Solutions

Pharma Grade Standard:

Aseptic filling process with precision insertion of tiny inner plugs, fully GMP compliant.

High-Value Liquid Packaging:

Specialized handling for dropper inserts to ensure tight sealing and reduce waste.

Biotech Applications:

Suitable for small-volume filling and capping of reagent tubes and buffer bottles.

FP-120 Specifications

| Bottle Range | 5ml - 100ml (Round & Irregular) |

|---|---|

| Capacity | 30 - 50 BPM (Liquid dependent) |

| Filling Accuracy | ±0.5% - 1.0% |

| Pump Type | High Precision Peristaltic Pump |

| Plug Types | Inner plugs, Dropper tips, Inserts |

| HMI Control | Mitsubishi PLC + 7" Touchscreen |

| Power | 220V / 380V 3-Phase, 50/60Hz |