Don't Let Fluid Characteristics Limit Your Production

Is your standard machine struggling with bubbles, stringing, or dosing errors?

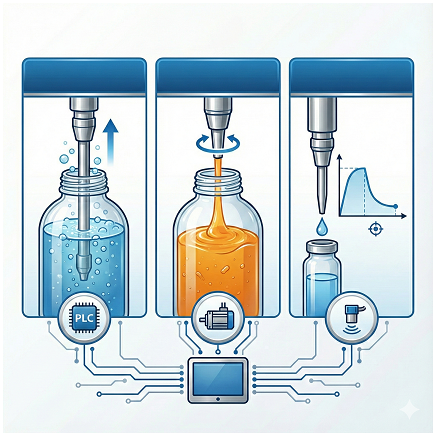

Hozun goes beyond hardware manufacturing. We engineer Custom PLC Servo Algorithms tailored to your specific fluid physics to eliminate bottlenecks:

1. For Foaming Liquids (Shampoos, Toners)

[ The Pain Point ] High-speed filling causes foam to overflow the bottle neck, forcing downtime for cleaning?

[ Hozun's Solution: Diving Nozzle Technology ] We program a servo-driven "Synchronized Rise" motion. The nozzle stays submerged just below the liquid surface while filling. This suppresses foam generation, enabling high-speed production with zero overflow.

2. For High-Viscosity Liquids (Gels, Creams, Honey)

[ The Pain Point ] Thick liquids leave messy "strings" or drips on the bottle or conveyor after the nozzle retracts?

[ Hozun's Solution: Anti-Drip Suck-Back ] We optimize parameters for "Vacuum Suck-back" and "Instant Cut-off" acceleration. By precisely controlling the servo motor angle, we ensure a clean cut with absolutely no dripping.

3. For High-Value Micro-Dosing (Eye Drops, Ampoules)

[ The Pain Point ] Are standard equipment errors causing significant cumulative waste of expensive raw materials?

[ Hozun's Solution: Dual-Stage Precision ] Adopting a two-stage variable speed logic (Fast Flow / Slow Dosing) to minimize error margins. Fully cGMP compliant, saving you substantial material costs.

Can't Handle Your "Special" Liquid?

Don't Compromise Your Production Speed.

Contact our engineering team directly via WhatsApp or Email for a free consultation.