3 Major Pitfalls in New Factory Planning

Don't wait for delivery to realize the equipment doesn't fit!

We understand more than just machines; we understand process engineering. Hozun provides "cGMP-Ready Layout Strategies" specifically for micro-filling lines (<100ml) to help you avoid these risks:

Hozun's Solution: Flow Optimization & Space Efficiency

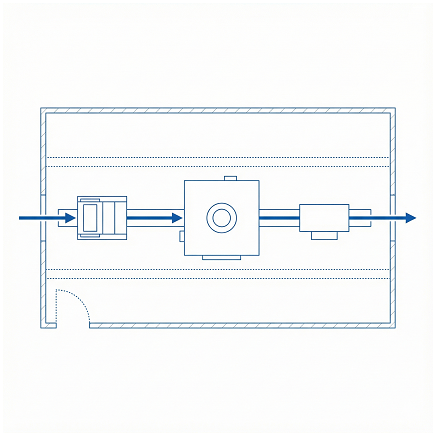

Is your factory plan still blank? Provide your floor plan (DWG/PDF), and we will design the smoothest Linear or U-shape workflow: from Bottle Washing → Sterilization → Filling & Capping → Labeling.

Strictly following cGMP/PIC/S guidelines, we plan independent routes for raw material entry, finished product exit, and personnel gowning/entry, maximizing protection against cross-contamination.

For high-cost cleanroom environments, we utilize compact "Monoblock" (All-in-One) equipment to save floor space, delivering high capacity even in small footprints.

Send Us Your Floor Plan Today

Let us perform a preliminary "Layout Health Check" for you.