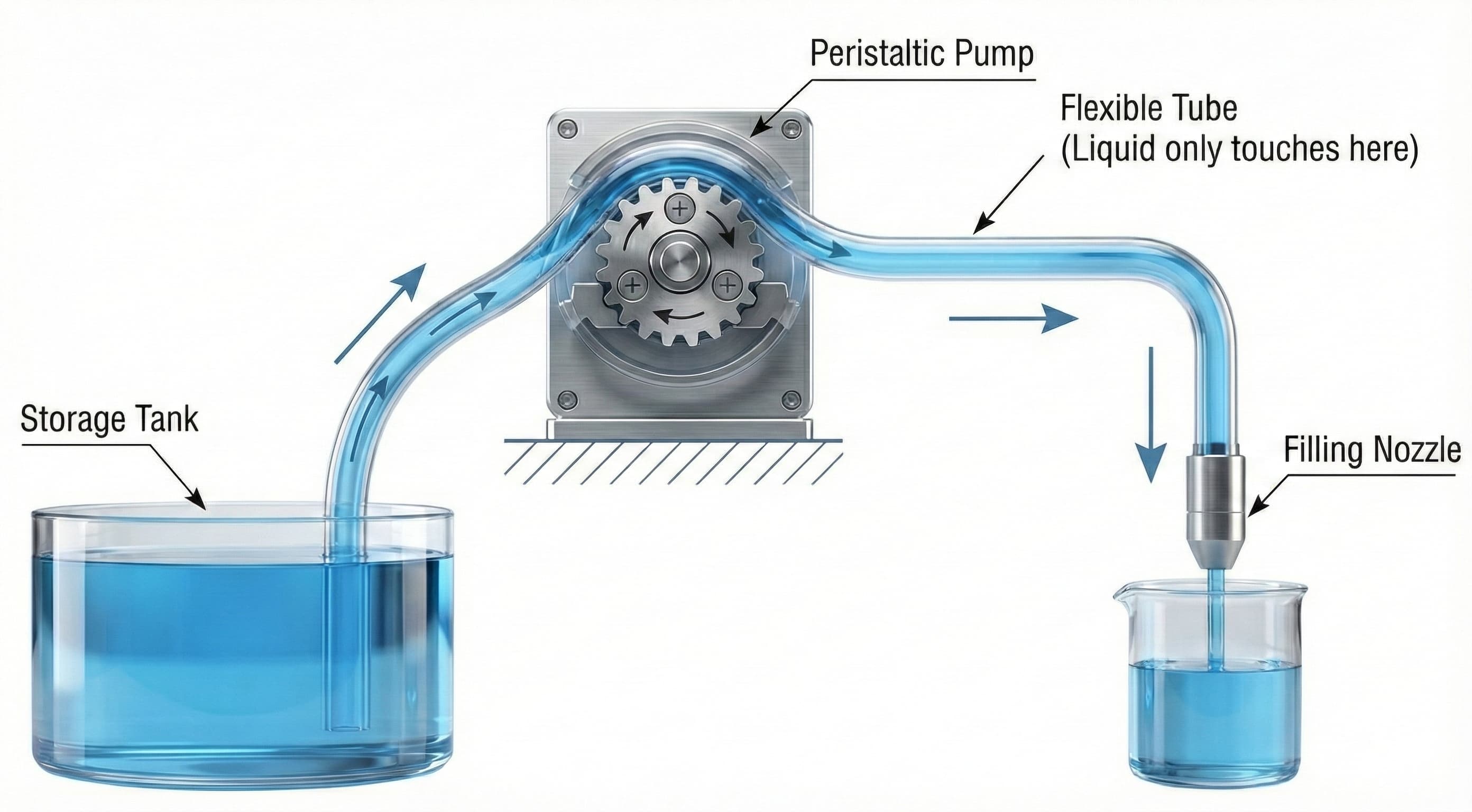

1. Peristaltic Pump Technology

▲ Fluid only contacts the tubing, ensuring zero cross-contamination.

Advantages: Rapid changeover (tube only), Contamination-free (Ideal for Biotech/Eye drops), Simple maintenance.

Limitations: Tubing is a consumable; slight accuracy drift over long-duration runs.

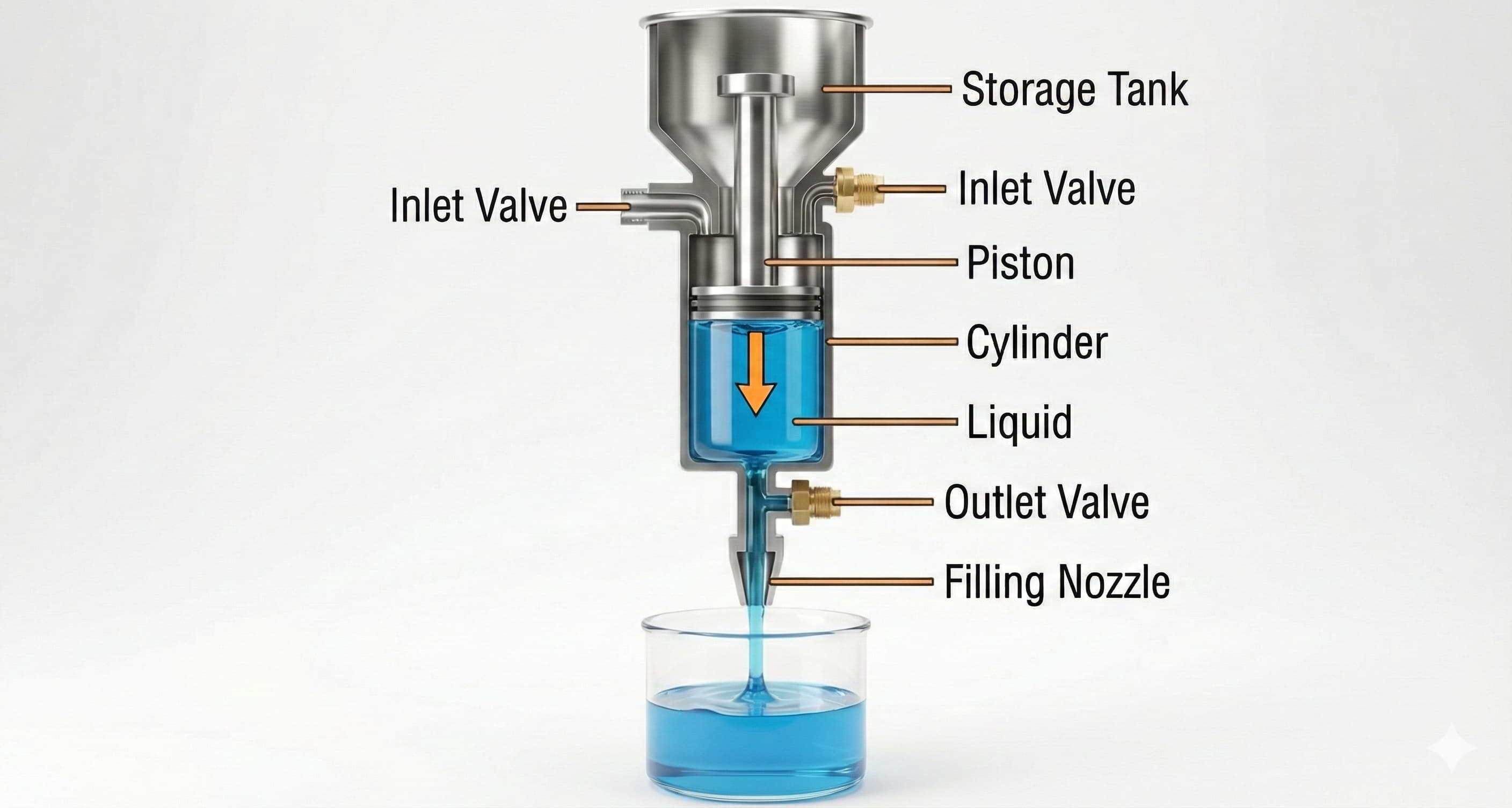

2. Piston Filling Technology

▲ Ideal for high-viscosity products and mass production.

Advantages: High repeatability, Handles high viscosity & particles (Sauces/Lotions), Durable.

Limitations: Longer cleaning/disassembly time; Corrosive liquids require special materials.

Engineer's Comparison Chart

| Feature | Peristaltic Pump | Piston Filler |

|---|---|---|

| Viscosity | Low ~ Medium (Water/Reagents) | Medium ~ High (Pastes/Oils) |

| Changeover | Very Fast (Tube only) | Slower (Cylinder disassembly) |

| Cleaning (GMP) | Excellent (CIP Friendly) | Good (Requires strip-down) |

Hozun's Recommendation:

- High Mix / Sterile Needs: Choose [ Peristaltic Pump ]

- Mass Production / High Viscosity: Choose [ Piston Filler ]

Not sure which one fits your product?

Get a free consultation & video demo from our engineers.